In this article I will about the aeronautical standard that is used by aircraft manufacturers such us Airbus, Bombardier, Boeing, Raytheon and so on. This standard is RTCA/DO-254. DO-254 is not used only by the commercial aircraft manufacturers but also used for military aircrafts.

The DO-254, also known as EUROCAE ED-80 (Design Assurance Guidance for Airborne Electronic Hardware), is a safety standard used during the development of airborne systems. The DO-254 doesn’t require the rules for the electronic design but the processes for hardware certification. It provides advice for the electronic hardware such us LRU (Line Replaceable Unit), SRU (Shop Replaceable Unit, CBA (Circuit Board Assembly), FPGA, ASIC, PLD, micro-controllers, micro-processors and COTS (Component Off the Shield).

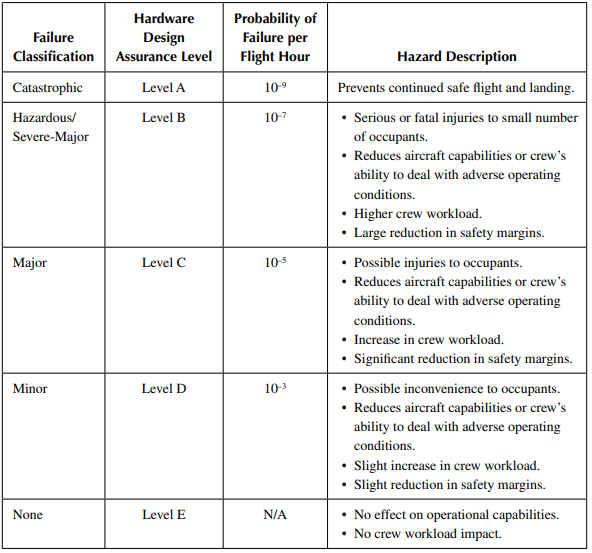

The standard DO-254 categorizes the electronic hardwares into several levels. These levels define the design assurance. These categorized levels called DAL into DO-254. DAL designates the Design Assurance Level. The Design Assurance Level (DAL) defines the electronic hardware / equipment according to their safety criticallity. There are 5 assurance levels and from A to E. Level A is for high critical equipments (e.g. altimeter, ice detector, radar, etc) and Level E is for equipment rather for the passengers’ and/or flight crew.

The below gives the necessary details of each DAL (Design Assurance Level). Thses DALs correspond to the the five classifications and of failure conditions.

Usually, the projects that aim to achieve DO-254 end up being more expensive than the projects without DO-254 applied. The overprices of the DO-254’s projects come from poor requirements management technics. The requirements are the core of the DO-254 and the ability to document, to analyze, to trace, to prioritize them and getting it right can make the difference between project success and failure.

Fortunately, the modern requirements management tools integrate support for risk management, test management, issue and defect tracking and change management into the same environment, helping to overcome the many challenges that can arise during the development of critical airborne electronic equipment.

Furthermore, the one of the important points in DO-254: Configuration management. It is mainly the baseline and traceability. The baselines are like taking a snapshot of a configuration item and making that snapshot a formal version (configuration) of the item that is then given a unique configuration ID. Roughly speaking, during the design and verification phases the files will go throughly many iterations so when the design begins to have a stable version, you are expected to baseline your design. This also allows you to find the configurations of the previous steps/reviews. Regarding the traceability, it is the activity in which two baselines of the same item are linked together or in other words there is a documentation trail between the two baselines.

Conclusion

Complying with the DO-254 standard can be a difficult and costly process, but a good requirements management tools, along with sufficient upfront planning, can go a long way towards bringing about DO-254.

As LaRocheNoire Technology, we plan training on the RTCA/DO-254 standard. This training will take care of all the documents to be generated, the reviews, the additional guides required and recommended by certification authorities to complete the DO-254 for a safe and reliable equipment. In the training there will be a .pdf document in which all the detailed contents explained, a powerpoint presentation and a video. We haven’t set the price for the DO-254 training yet but it will be reasonable (between 700$ or 900$).

Give us your opinion in the comment below and let us know if you are interested in this training.