The desire to explore space and to become better in the field has pushed engineers, scientists and companies to develop techniques and technologies that facilitate the implementation of high-performance satellites as well as to develop small sized satellite equipments. Thanks to the new standards published and the existing standards updated, we are developing space equipment that is more and more reliable, robust and safe.

In this article I would like to deal with the standard on which I am currently working for more than a year and a half which is the ANSI/VITA 74 also known as VNX. A small form factor module standard.

It was designed from scratch up to be inherently rugged and conduction cooled for space applications. It is downscaled derivated of VPX (VITA 46 & 65) with similar architecture but at a smaller size, lower power consumption and cost.

The VNX has documentation that takes into account the electronic and mechanical considerations necessary to implement solutions to reduce radiation tolerances to a minimum in small spacecraft applications (satellites, rovers, telescopes, etc.).

Another advantage of VNX is that it can also be extended for use in high-speed fabrics using coaxial and optical signals. VNX connector modules have been designed for various signaling combinations such as fiber optic connectivity, coaxial connectivity (for RF and video signals).

The VNX also supports signal processors like DSP, Graphics Processing Units (GPU), FPGA, I/O modules that require optical signals. These applications require high speed connectors with a full connector. VITA 90.3 describes the standard for implementing VNX+ compatible power conversion and energy storage plug-in modules in VNX+ systems. So the VNX+ could be implemented into the VNX based equipements easily.

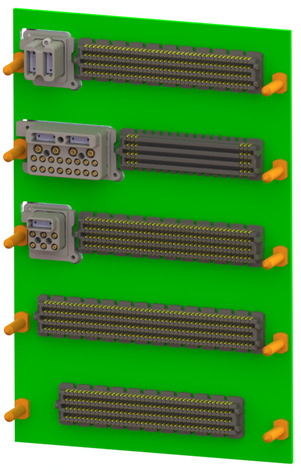

Through careful ingenuity of thermal and mechanical considerations, VNX+ modules can easily integrate into many systems using conventional backplanes for single-module deployments. If your applications require additional spaces, they may be recovered by using an equivalent cabled backplane. Figure 2 shows the VNX backplane.

To conclude, there is no limit to develop an space applications such as small-sized satellite, military equipments, aircraft equipments, etc. So the military and aerospace manufacturers move to smaller and performant systems and these kind of systems become more and more important and essential. There is no obligation to use existing systems developed for over-sized equiments compared to specific needs. For example, to develop nanosatellites, the VNX solution is a perfect solution for that kind of application. No need to spend money and time in order to develop a new system from scracth. To minimize the effort spending required to upgrade the HW and I/O interfaces, it necessary to design a HW complies with ANSI/VITA.